Wood plastification by ammonia is process of treatment less valued types of broadleaved species, during

which are significantly changed mechanic and aesthetic properties of wood.

Experiments performed within the international cooperation between CSSR and USSR were terminated due to

lack of machinery capacities and resulted only in start-up of the testing operation in Daleké Dušníky with

subsequent production reaching 270 m3/year, confirming feasibility of ammonia wood plastification technology.

By plastification the changed properties across the entire section of the substance are achieved.

The specific weight of the plastified wood is reaching 800 – 1300 kg/m3. When comparing this product to the

imported ebony wood it results heavier by

300 kg/m3 in the specific weight.

For the purpose of comparison to other technologies we have no data available because there is no known

world manufacturer of the comparable product.

If we compared all properties of the plastified wood we would reach a conclusion that this product would find its

use not only in our but also in the foreign market because market research indicates that there is a great interest

in this commodity.

PRESSING THE BEECH WOOD

| Pressing [%] |

Volume [kg/m3] |

Comparable material |

|---|---|---|

| 0 | 650 - 680 | Beech [680] |

| 20 | 820 - 830 | Teak [820] |

| 27 | 880 - 900 | Mahogany [850] |

| 30 | 930 - 950 | Palisander [1100] |

| 50 | 1200 - 1300 | Ebony [1300] |

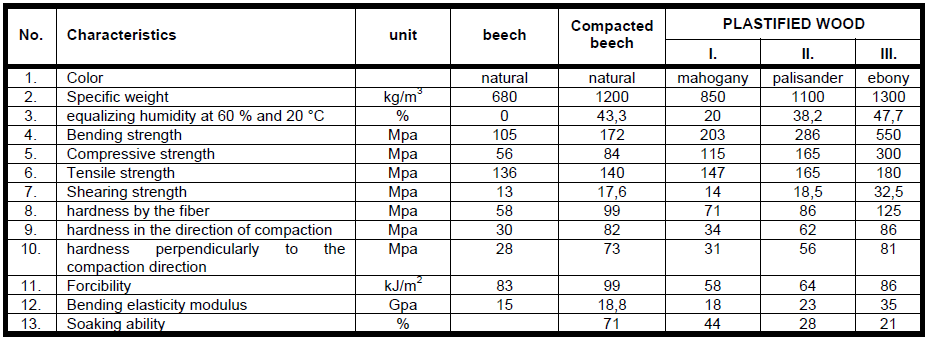

By ammonia wood plastification an improvement in mechanical values is reached also for the low quality tree species at increased resistance against to cracking, rotting, scolding, soaking and at the same time at in significant improvement of the decorative properties. The final product made of plastified wood is fully comparable by its look, life-span and utilization properties to the imported exotic tree species such as EBONY, TEAK, PALISANDER or MAHOGANY. It substitutes also some non-ferrous metals and plastics. Many characteristics of plastificated wood has significantly better performance than exotic plants.

Its excellent physical and mechanical properties were verified by the laboratory tests according to ČSN 490101 in the testing facility of the Forestry and Wood Technology Faculty of Mendel Agricultural and forestry university in Brno during the month of October.

Physical, chemical and mechanical characteristics are specified in the following table being compared to the classical tree species:

PHYSICAL, CHEMICAL AND MECHANICAL CHARACTERISTICS OF THE PLASTIFIED WOOD

The values has been measured on the samples from the research semi-operation in Daleké Dušníky.

Specimen tube

Proposal