Results of development is operational example of flange joint DN50.

It is assumed a development the full class of type flange joint with clarity DN25–DN150.

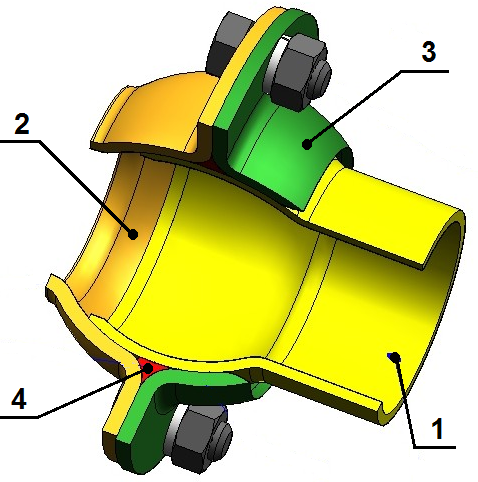

The joints consist of

- quiver (pos.1) at the end measures spherical surface

- neck (pos.2) arrangements with flange and spherical surface

- the next neck (pos.3), which is furnished with flange and spherical surface

- flexible seal (pos.4) and

- screwing joint (pos.5).

Midpoint of sphericals surface quiver 1, neck 2 and 3 are consistent and lie upon axis piping with quiver 1. Marked structure makes it possible a swinging of quiver 1 towards neck 2 and 3.

Flange of neck 2 and of neck 3 are coupled with screwed joint 5. Flange of neck 2 and flange of neck 3 fit at each other and is not generated any additional deflection stress of flanges.

Space between spherical surface of quiver 1 and transitional radius of flange of neck 2 and 3 is replete with elastic seal 4. Screwing together of flange neck 2 and 3 is compressed a elastic seal for reaching a tightness of join. while increase the pressure, is a sealing action reached with compression of seal 4.

Seal has a special profile providing tightness for defined space between seal and spherical surface of quiver 1 and transitional radius flange of necks 2 and 3.

Quiver 1 and necks 2 and 3 are produced with coldpressworking, designed and verified technological practice.

Together with development is provided a patent protection of new flanged join.

Benefits of new joints

Joints overview

Ordering conduct

Website Template created by WebTemplateBiz, modified by PegasTECH