Flange joints - Benefits of new joint

CUT DOWN A FLANGE JOINT WEIGHT

Defined version of flanged joint makes it possible important cut-down of joint weight. Next will documented specific results attained at functional example DN50 which was document upon analyses state of stress with method of finite element and comparision with standard flange joints as equivalent dimensional specification for metal flange ISO 2084-1974 (DIN 2501). For providing comparable conditions come out for flange joint DN50 from defined length of flange joint 90 mm. Comparison be evident from following table| Joint type | Operating pressure [MPa] |

Experimental pressure [MPa] |

Measurements of flange [mm] |

Joint weight [kg] |

Screw connection |

|---|---|---|---|---|---|

| New joint DP25 | 2,5 | 5 | D 122-4 | 0,97 | 4xM10 |

| New joint DP50 | 5 | 10 | D 122-4 | 0,97 | 8xM10 |

| ISO DP06 | 0,6 | - | D140/ D60-12 | 2,78 | 4xM12 |

| ISO DP40 | 4 | - | D165/ D60-16 | 4,44 | 4xM16 |

Assumed values of nominal and experimental pressure was at functional example of joint DN50 verificated in pressure test. The flange joint with 4 screws was joint multiply loaded with test pressure 5MPa and flange joint with 8 screws was multiply loaded with test pressure 10MPa.

TWO DEGREES OF FREEDOM IN ASSY TIME

In time installation is possible ramble 1, which is welded to piping, swinging in two tendency which makes it possible a simplification if setting at installation. Changing position of ramble 1 towards neck 2 and 3 is possible in the working condition, tighting of joint remain unchanged.Joint look like toggle, eliminate potential additional stresses implicit from potential motions of piping systems. With reference to elasticity of joint is new flange joint especially useful to regions with increase of seismicity. Important can be exploitation for flexible systems with bigger deformations, e.g for piping system ships.THREE DEGREES OF FREEDOM

Joint was work off for the third degree of freedom- as technological stage with exploitation of assembly welding seam

- as type of junction for ability of three degrees of freedom for assembly in time operations too.

Individual joints are presented in joint overview.

SIMPLIFICATION OF ARMATURE CAST STOCKS AND CUT-DOWN OF THEM WEIGHT

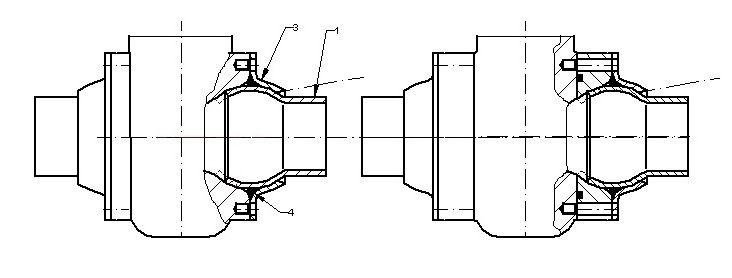

Special interesting field for application of new flanged joints is region of armatures, practicaly relapse four flanges. On cast stock bodies of armatures come to expressive simplification of cast stocks and to expressive cut-down them weight. Application of flanged joints on armatures is displayed on pic.2 and pic.3. |

|

|---|---|

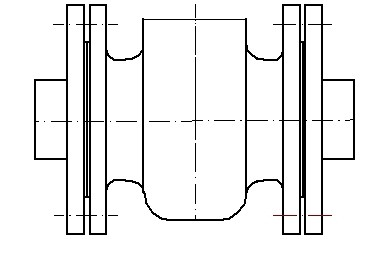

| pic.2 Classic junction of flange joint on armatures with piping |

pic.3 Alternative of solution junction for armatures and new flange joint |

Displayed is ability straight assembly ramble 1 to body of armatures as well as design of solution for application a flange joint with two of degrees of freedom, providing, that is asking for exchange of armatures without dismantling piping system. New flange joints with two degrees of freedom makes it possible expressive increase of working pressures. Analysis is made for functional example flanged join DN50 by using 4 and 8 screw and is compared with finishies test pressures of functional example.

CLOSURE

From description, analysis and exams of functional example can we allege, that new flange joint with two degrees of freedom (in case of need of three degrees of freedom), toward standard flanged joint- present 40 - 75% cut-down weight of flange joints

- makes it possible two eventually three degrees of freedom for installation and operation

- important use finds especially for exploitation at flanged armatures

- joint especially useful to regions with increase of seismicity

- finds exploitation at flexible system with bigger deformity, e.g . for piping systems of ships

Executed computing analyses make possible to define marginal values allowed loading working pressures in pipeline systems in dependencies of clarity flange joints and in dependencies on a count of screws.

Product description

Joints overview

Ordering conduct